Red-Ant Measurement Technologies and Services GmbH

Correspondence: Deutsch, English

Foundation: 2004

Operation Level: Regional, International, National

80807 Munich Germany

Phone: +49 89 306 58 99 0

Fax: +49 89 306 58 99 99

Web: http://www.red-ant.de

|

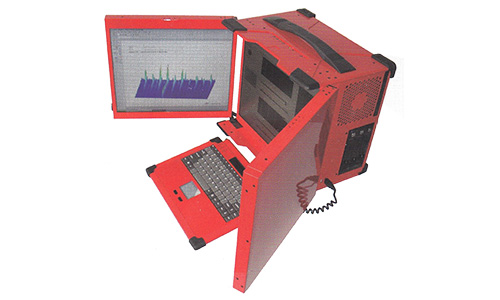

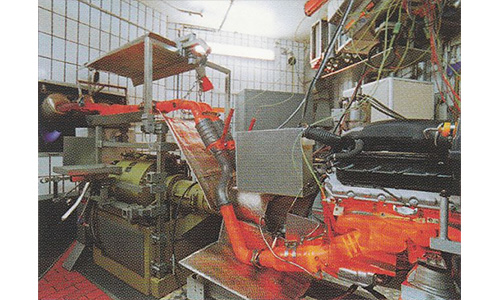

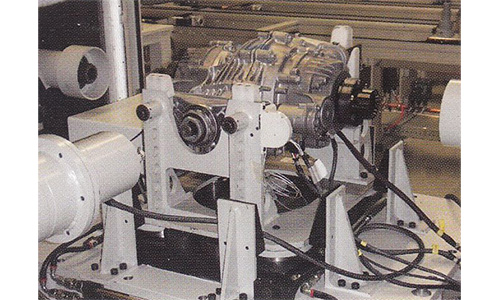

Based in Munich Germany with technical representatives worldwide, red-ant is a competent partner for complete vibration analysis solutions. Our product and service portfolio encompasses optimally tailored measurement technology and specialist services for applications in automotive manufacturing and machinery construction. Over 80 satisfied industry customers around the world utilize the high-precision red-ant systems for early failure detection and quality assurance.

|

International research, testing and industrial instrumentation exhibition

23/10/2018 - 24/10/2018

Location Paris expo Porte de Versailles

Paris

France

International trade fair of automotive testing, evaluation and quality engineering

24/10/2023 - 26/10/2023

Location Novi Exposition Center / Suburban Collection Showplace (formerly Rock Financial)

Novi

United States of America

International measurement industry exhibition

11/06/2024 - 13/06/2024

Location Nuernberg Messe

Nuremberg

Germany

International trade fair of automotive testing, evaluation and quality engineering

28/08/2024 - 30/08/2024

Location Shanghai World Expo Exhibition & Convention Center

Shanghai

China, P.R.

International trade fair of automotive testing, evaluation and quality engineering

23/06/2026 - 25/06/2026

Location Messe Stuttgart

Stuttgart

Germany