|

Bradley Pulverizer was founded in 1886 and was based in Allentown, Pennsylvania because of the rich limestone deposits of the area. The first pulverizers produced were for the cement industry but later they were used in many other areas.

Bradley began manufacturing the renowned single roll Griffin Mill in 1886 and, since then, has strived to supply our customers with the most economical, reliable, maintenance-free, energy-efficient pulverizing system available by incorporating the latest developments.

We have equipment operating in over 40 countries in a variety of industries, including cement, steel, fertilizer (phosphate), petroleum, (barite and bentonite), mineral fillers, clay, coal, utility (limestone grinding for SO2 removal), pulp and paper, chemical, pigments, building materials, etc.

Our mills are also particularly well suited for many plant operations requiring finely ground mineral products for use in industries such as cement, phosphate fertilizer and steel.

As specialists in the design, manufacture and supply of pulverizing systems for fine and semi-fine grinding of hard, friable, abrasive materials for various applications throughout the world we can supply you the optimum system from our complete line of pulverizers, ranging in output from 1 to 150 tons per hour, which can be adjusted to produce a uniform particle size, ranging from 50% passing 150 micron to 100% passing 30 microns in a single pass.

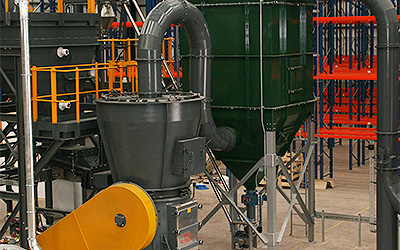

Today, our pulverizing mills are called centrifugal ring-roll type pulverizers. They consist of three pendulum-type roll assemblies suspended from a rotating carrier. Centrifugal force, created by the rotation of the carrier, causes the roll assemblies to swing outward causing the roller at the bottom of the roll assembly to rotate against the inside of a stationary ring. The material is picked up by plows and directed between the roller and ring where it is ground using a combination of attrition and impact. When the material is ground to the desired fineness, it is sized and discharged from the mill via a screen when semi-fine grinding or via air when fine grinding.

|