|

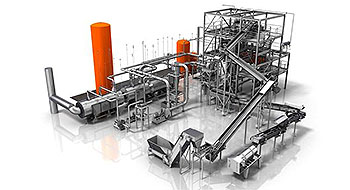

Airco DIET is the World Leader in Tobacco Expansion with more than 60 DIET (Dry Ice Expanded Tobacco) Plants built worldwide over its 30 year history; many of which have been turn-key installation projects. 20 DIET Plants have been built by Airco DIET over the past 10 years, enabling continuous product development, while supplying the markets' most advanced and reliable DIET plants, producing the best possible DIET product.

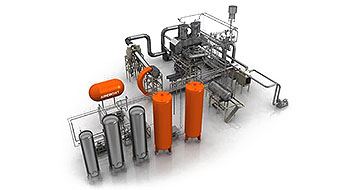

The constant commitment to innovation within Airco DIET has led to the introduction and commercialization of the "C" Tower in the DIET Plant Hot End, which provides highly improved heat transfer during the drying process, with much higher product yield and significantly less degradation of the expanded tobacco product. Other recent improvements include the addition of a 3rd stage CO2 recovery unit to minimize CO2 usage and have a more environmentally friendly operation and further, now under development, a completely new standardized small 300 kg/hr DIET Plant, which allows for both much lower capital and installation costs.

Airco DIET is a household name for high expansion within the tobacco industry. The DIET process itself was invented and patented as a joint venture between Airco DIET and Philip Morris and today all major players in the cigarette industry own DIET plants.

The DIET process is an effective tool for tar and nicotine reduction in cigarettes using tobacco laminar; it also reduces the bulk density of the cigarette blend which significantly reduces the cost of manufacturing with utility production costs of less than ?1/kg of produced DIET tobacco. Today's inclusion rate of DIET in premium cigarettes is therefore also 20% to 30%. DIET provides product designers and developers a true tool with which to achieve desired cigarette taste, quality and delivery properties.

The first DIET plants were built by Airco DIET 35 years ago in 1987 but these first plants where significantly different in design even though the basic process remains the same. The DIET plants have evolved radically over the years and there have been significant improvements introduced.

A modern DIET plant has an uptime above 95% with a DIET dry weight yield above 98.5%.

|